CNC Machining in Valencia

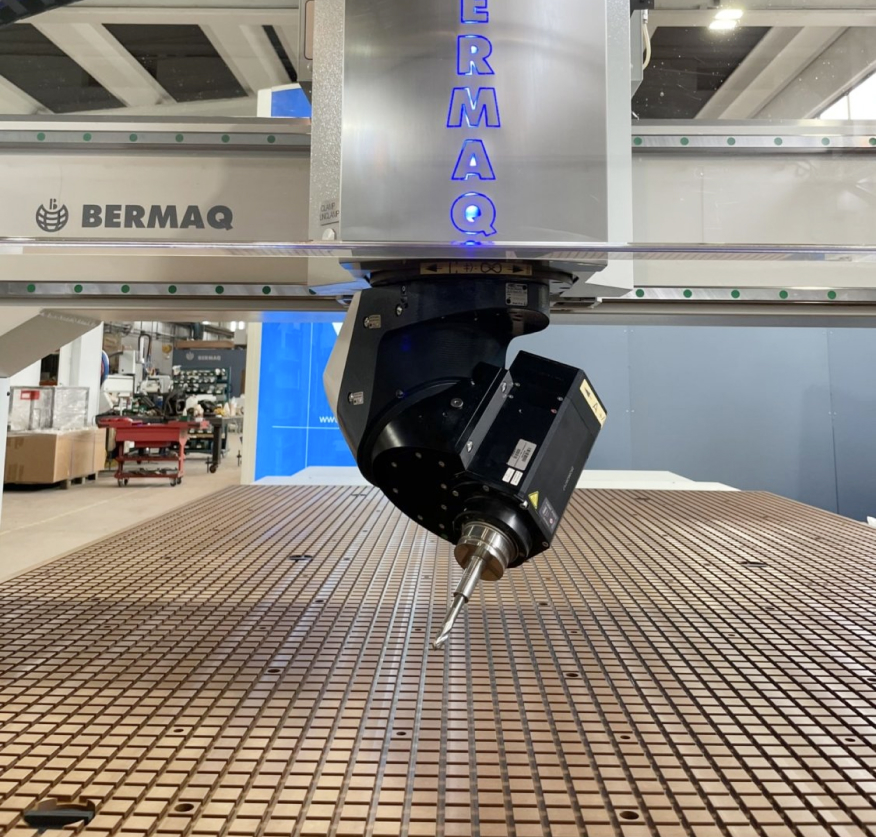

At Indutec Solid, we have three 5-axis machining centres, capable of working with a wide variety of materials, from wood to thermoplastics.

At Indutec Solid, we have three 5-axis machining centres, capable of working with a wide variety of materials, from wood to thermoplastics.

At Indutec Solid, based in Valencia, we pride ourselves on being pioneers in the field of CNC machining Valencia. Our focus is on the use of 5-axis machining technology, supported by our experts in the technical office, who transform 3D geometries provided by our customers or designed in-house into high-precision machining solutions. This advanced technology enables us to handle a wide range of materials, including wood, boards, plastics, laminates, composites and technical materials.

With a working capacity of 4900x2500x1000 mm, our equipment is capable of both simple cutting operations and the most complex customised configurations. This approach allows us to adapt to the specifications of architectural, construction, interior and design projects with exceptional precision. We ensure that each piece not only meets expectations but also sets new standards of quality and innovation in the industry.

Indutec Solid sets the standard in CNC panel machining in Valencia thanks to our state-of-the-art technological infrastructure. Our 5-axis machining centres, which offer a large working volume of 4900x2500x1000 mm, allow us to tackle large-scale projects with unsurpassed efficiency and precision. The integration of overhead cranes and the ability to operate in three shifts per day significantly increases our production capacity, allowing us to meet the most demanding market requirements and maintain a competitive edge in CNC machining in plastics in Valencia.

This infrastructure not only facilitates increased production but also guarantees the delivery of products that meet and exceed the most rigorous quality standards. At Indutec Solid, each project is treated with the utmost professionalism and technical precision, ensuring results that not only meet the client's needs but also contribute significantly to the success of their initiatives.

Over 2,000 m2 of facilities equipped with the latest technology to conceive complex and ambitious projects

In our 3 machining centers, we work with workpiece volumes of up to 5000x2300x1000 mm, leveraging TopSolid software to exploit all possibilities for producing parts with reliability and precision.

We leverage the use of different thermoforming technologies, adapting to the characteristics of the material and the complexity of the geometries required by each project.

Where we are?