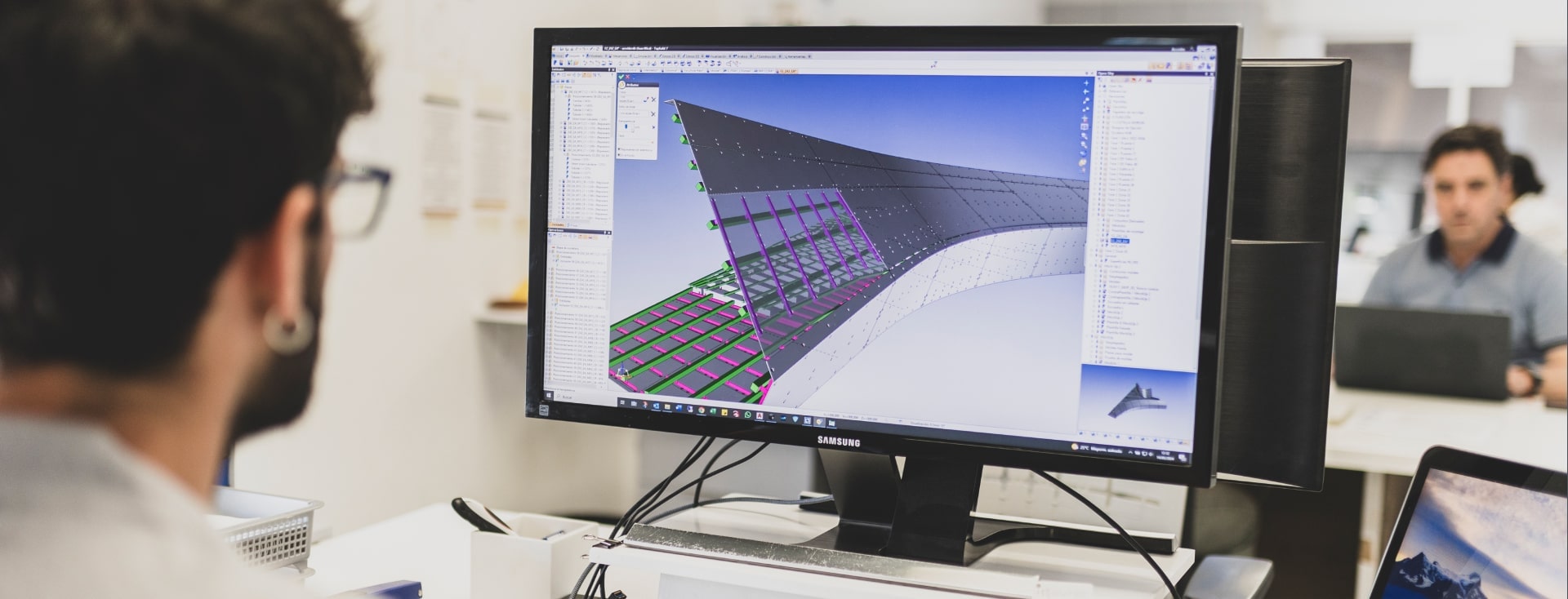

Machining and processing of thermoplastics, methacrylate and advanced materials

The possibility we offer of working with these products greatly facilitates the work of any designer. The variety of materials within this family, its range of finishes and the versatility offered by thermocurving are highly valued characteristics in the field of industrial design.

ADVANTAGES

Why choose Plastics, Methacrylate and Advanced Materials?

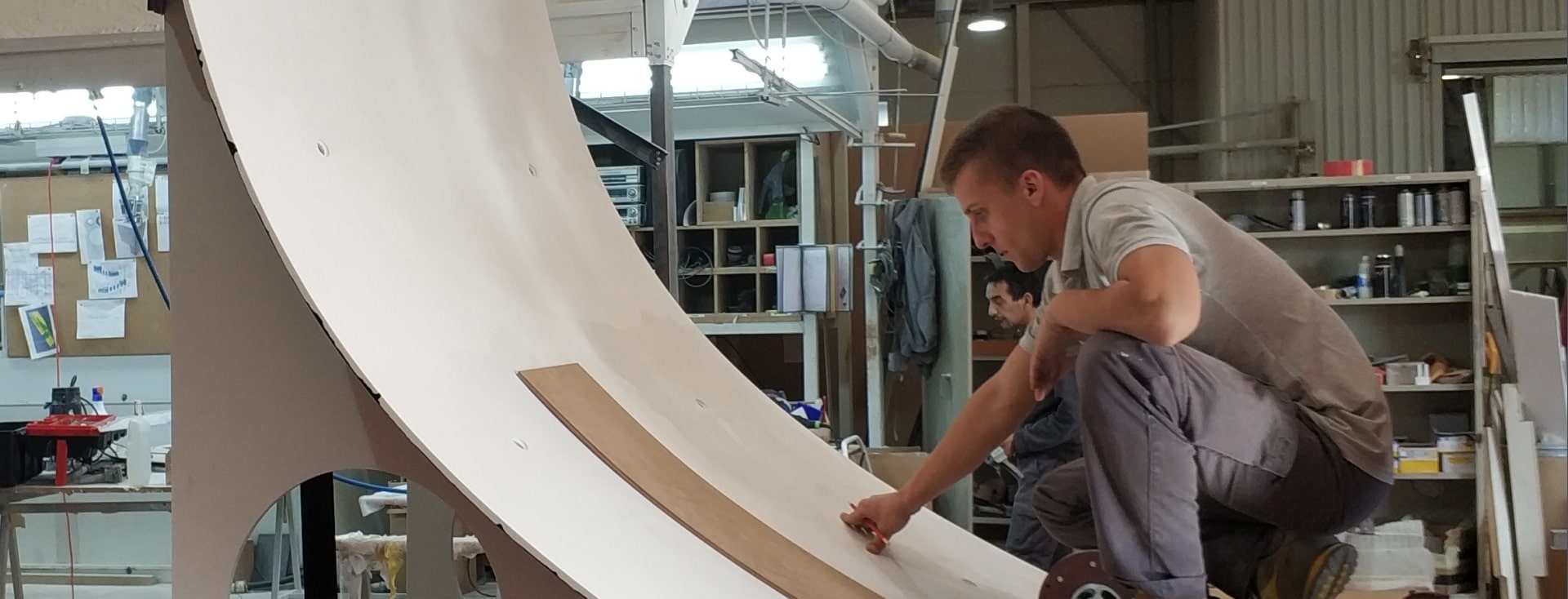

Very tight costs

The cost of a thermoformed product is more competitive for short runs than one made by injection moulding or other processes. As we have our own means to carry out all stages of the process, we offer the best value for money.

Lightweight but strong

Thermoplastics are lighter than other materials such as metal or wood, which makes them easier to handle and install. They are also resistant to impact, moisture and chemicals, which ensures greater durability and less maintenance.

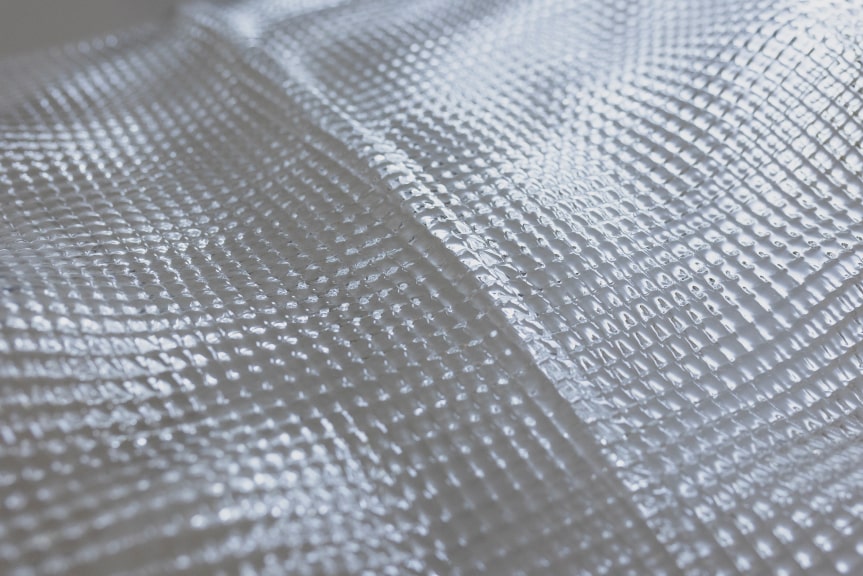

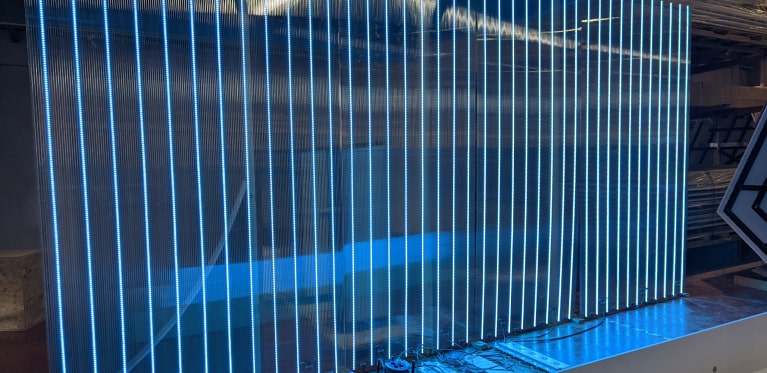

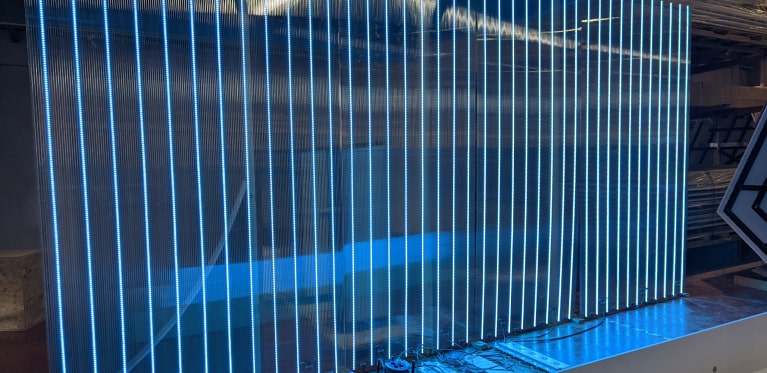

High degree of transparency

Thanks to this property of plastics and methacrylates, it is possible to create surfaces with glossy, matt or translucent finishes, which expands the aesthetic possibilities in interior decoration and retail applications.

Projects

Explore our selection of projects

FAQS

Frequent questions

Do you have any doubts about the use and maintenance of plastic materials, methacrylates and advanced materials? Visit our frequently asked questions section to clear them up.

Methacrylate parts can be cleaned with a soft cloth and neutral soapy water. Avoid using abrasive cleaners as they may scratch or damage the surface. To maintain its shiny appearance, specific products for acrylics can be used to help prevent scratches and maintain the shine.

Plastics offer several significant advantages in interior decoration. They are lighter, making them easier to handle and install. They are also resistant to moisture and chemicals, making them ideal for areas with high humidity or where frequent cleaning is required

Using recycled plastics in interior design is a sustainable option and can be as safe and durable as virgin plastics, provided that high quality products are selected. It is important to ensure that recycled plastics have gone through a proper recycling process.