Indutec Solid was founded in 1995 as a company dedicated to the machining of parts for the wood sector. Since 2000, we have had a constantly growing engineering team that enables our customers to develop all kinds of projects.

If we add to the versatility offered by the wide range of materials we work with the experience of our Technical Office and the capacity of our facilities (5-axis machining centres, thermoforming furnace, membrane press, etc.), the result is the possibility of offering our customers the solution to all their needs

Indutec Solid was founded in 1995 as a company dedicated to the machining of parts for the wood sector. Since 2000, we have had a constantly growing engineering team that enables our customers to develop all kinds of projects.

If we add to the versatility offered by the wide range of materials we work with the experience of our Technical Office and the capacity of our facilities (5-axis machining centres, thermoforming furnace, membrane press, etc.), the result is the possibility of offering our customers the solution to all their needs

INDUTEC SOLID opened its doors in 1995 in Silla, as a machining workshop serving the furniture industry in Valencia. We started with 2 machining centres (CNCs) of 3 and 4 axes, and in the year 2000 our Technical Office was born with a clear objective: to offer reliable results, reduce response times and transmit greater confidence to our customers.

On 24 December 2001, in the interior of our simplest CNC, late in the afternoon and with the workshop closed, combustion broke out and started a fire. Thanks to the alarms and the rapid response of the fire brigade, the fire only affected the machining centre and its immediate surroundings, forcing us to renew the machinery.

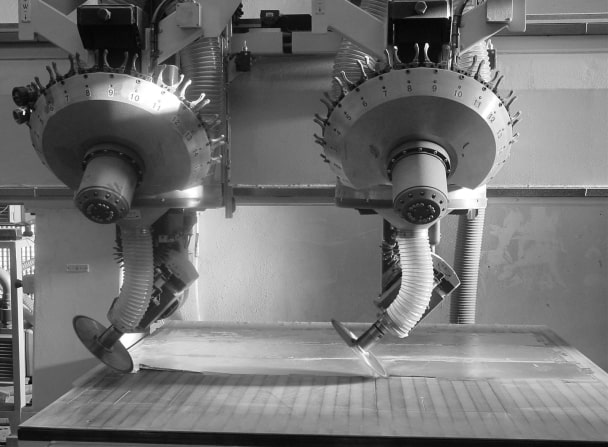

This is when the decision was taken to incorporate a new, more advanced machining centre, with two 5-axis spindles. This small fire put us in a very visible position with respect to our competitors, improving the training of our Technical Office and opening up a series of new creative possibilities that awakened the spirits of the whole team.

What at first seemed like a misfortune, ended up being a Christmas present that increased our client portfolio and started the first technical projects outside the furniture sector’

At the end of 2005, our main customers were affected by changes in the production sector, which seriously affected the growth of our company. At the end of 2007 and thanks to the 1st Indutec Solid website, created by a child, son of the company, the firm ‘’System Pool‘’ contacted us and we started our first collaboration outside the wood sector. With them we discovered Solid Surface, and thanks to this relationship our company was saved from almost certain closure.

In this new environment, we took advantage of the opportunity to strengthen and enhance our technical office, especially in the more creative and highly valued area of architecture.

Because of this stone in the road and many others, at Indutec Solid we have learned that crises and big problems are great opportunities for improvement and new incentives. For this reason, we are passionate about projects of a certain constructive complexity and development, we enjoy the process and the search for solutions

In 2012, new technologies came to Indutec to stay. The incorporation of TopSolid marked a new technological milestone for the company. As a high-level, parametric and relational mechanical software that drastically reduced errors in assembled sets of elements, we improved the design of the parts as a whole and ensured satisfactory production.

The ability to make changes to parts and apply those changes to all related elements (moulds, assembly jigs, CNC machining programs, etc.) streamlined many processes and opened doors to new possibilities.

Working with TopSolid software and our in-house developed CAM application for AutoCAD, we gained an ability and productivity to work on projects with many unique and complex parts, and offer our customers certainty of results

With the rapid growth of the company and the Solid Surface ventilated façade projects, which already had thousands of m2 of production, in 2014 we were forced to move to Paiporta (Valencia). This move allowed us to expand the production area to more than 2000m2, developing in turn an optimised operation and adding to our 3 CNCs a new fleet of equipment:

- Well adapted final finish sanding area, with high vacuum suction system for manual sanders.

- Wide belt sander for large panels.

- Air/silica filter that collects by high volume suction the dust generated by CNCs and other machines.

- Assembly area with large calibrated tables (6x2.5m) and multi-purpose work tables for smaller products.

- Double gantry crane for handling large-volume parts.

- Larger office with Citrix virtualised application and graphics servers.

These significant improvements enabled us to make the leap to large-scale production that we now champion.

We infuse our work methodology with an avant-garde and innovative style. Our commitment: to adapt and create solutions for your project.

More than 2000 m2 of technology and specialised machinery to take your project one step further