Industrial carpentry in Valencia

At Indutec Solid, we transform visions and ideas into tangible realities with our expertise in industrial wood carpentry.

At Indutec Solid, we transform visions and ideas into tangible realities with our expertise in industrial wood carpentry.

At Indutec Solid, located in Valencia, we stand out for our ability to handle any industrial wood carpentry project, adapting to the specific needs of each client. Our experience allows us to offer furniture design and manufacturing solutions that not only meet, but exceed expectations in terms of quality and functionality. From conceptualisation to execution, our technical office provides unrivalled value in the design and development phase. Thanks to our versatility in handling a wide range of materials, including those provided by our clients, we guarantee complete and efficient customisation of each piece.

We specialise in industrial wood joinery projects for the retail sector and contract spaces, designing bespoke furniture that integrates perfectly into each environment. Our ability to combine different materials allows us to optimise costs without compromising quality. In addition, our transport and installation logistics enable us to deliver and install anywhere in the world, ensuring a complete service from the first contact to the completion of the project

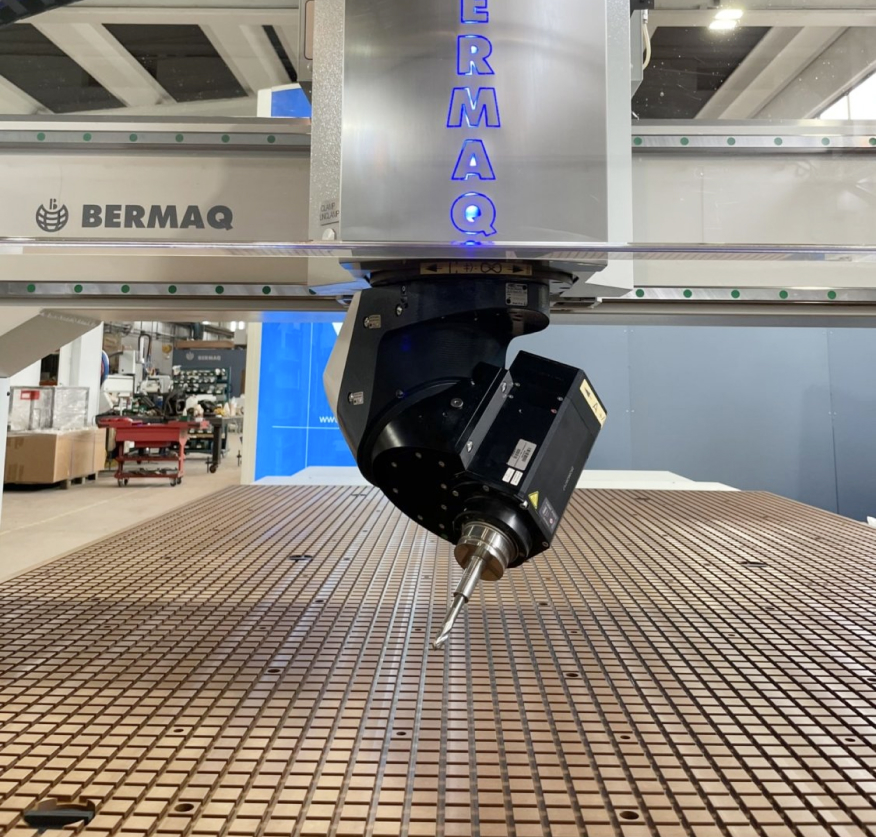

At Indutec Solid, located in Paiporta, Valencia, we pride ourselves on our ability to tackle industrial woodworking projects of any size thanks to our advanced technology and extensive facilities. Our equipment includes three 5-axis machining centres, capable of handling dimensions up to 4900x2500x1000 mm, allowing us to carry out precise work on large scales. In addition, we have a plane sander that ensures flawless finishes and a squaring machine for accurate and efficient cuts. Our hydraulic press facilitates the handling of materials under high pressure, which is essential for certain manufacturing processes.

In addition, we have a thermocurving furnace and a specific press for shaping materials, which extends our range of design and production. Our factory's overhead cranes are crucial for the safe and efficient handling of heavy and bulky materials, optimising workflow and productivity. This combination of cutting-edge technology and highly skilled personnel allows us to constantly innovate and meet our customers‘ most demanding requirements, maintaining a superior quality standard in all our industrial joinery projects

Over 2,000 m2 of facilities equipped with the latest technology to conceive complex and ambitious projects

In our 3 machining centers, we work with workpiece volumes of up to 5000x2300x1000 mm, leveraging TopSolid software to exploit all possibilities for producing parts with reliability and precision.

We leverage the use of different thermoforming technologies, adapting to the characteristics of the material and the complexity of the geometries required by each project.

Where we are?