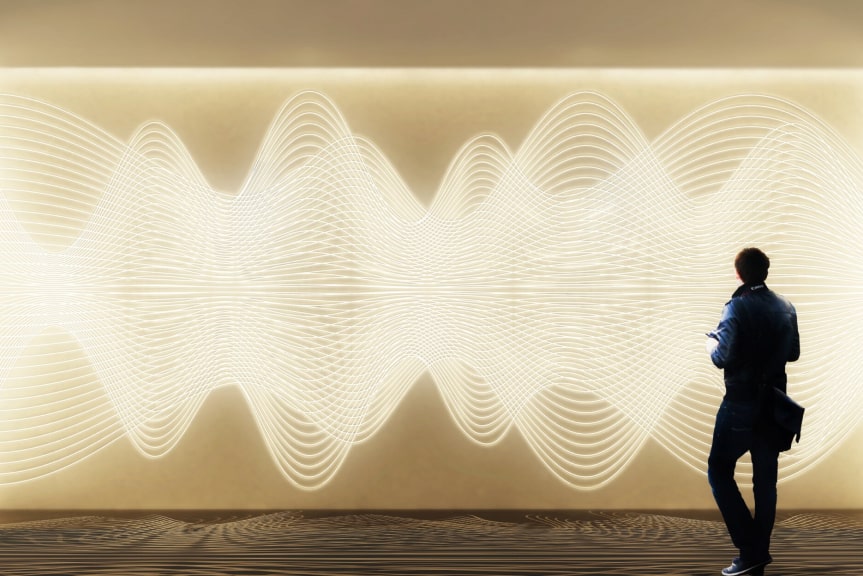

Solid Surface machining, the fusion of adaptability and design

Solid Surface is a unique and very versatile material, as well as technologically advanced due to its characteristics and resistance and its composition: natural mineral fillers and acrylic resins. It is a solid product, very hard, compact, non-porous and totally homogeneous.

Advantages

Why choose Solid Surface?

Ease of cleaning

Its non-porous surface is easy to clean and resistant to the growth of bacteria and mould, providing a more hygienic environment in areas such as kitchens and bathrooms compared to materials such as wood, marble or natural stone.

Easy repair

Solid Surface stands out from other materials because of its ease of repair. Any knocks, stains or scratches can be easily repaired, and this feature of the material can also be used for maintenance after prolonged use.

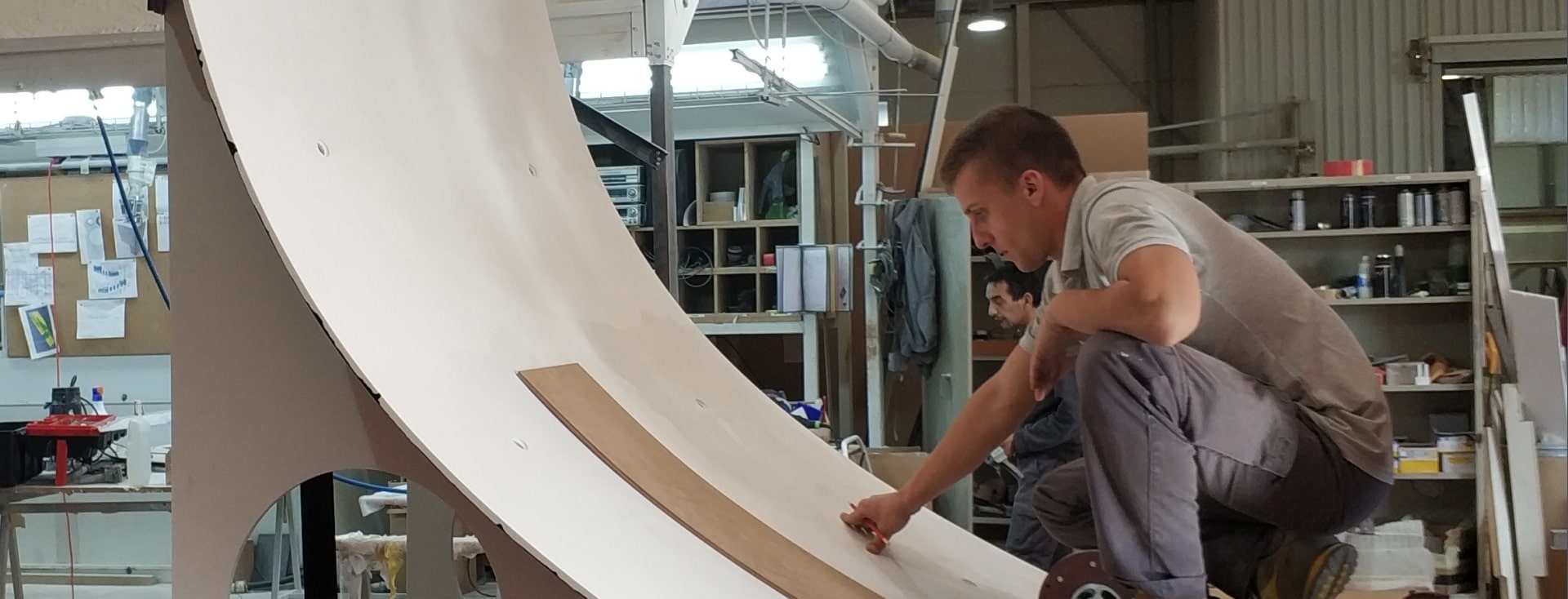

No visible joints

This is one of the most appreciated advantages of Solid Surface over other materials such as marble or granite, thanks to the joint welding techniques, large pieces can be made without any noticeable joints.

Projects

Explore our selection of projects

Frequently Asked Questions

Do you have questions about the use and maintenance of Solid Surface? Take a look at our FAQ section to clarify them or contact us.

Solid Surface is a material composed primarily of acrylic resins and natural minerals, designed to offer durability and versatility in a wide range of applications. It is commonly used in kitchen and bathroom countertops, wall coverings, furniture, and commercial and healthcare applications, among others.

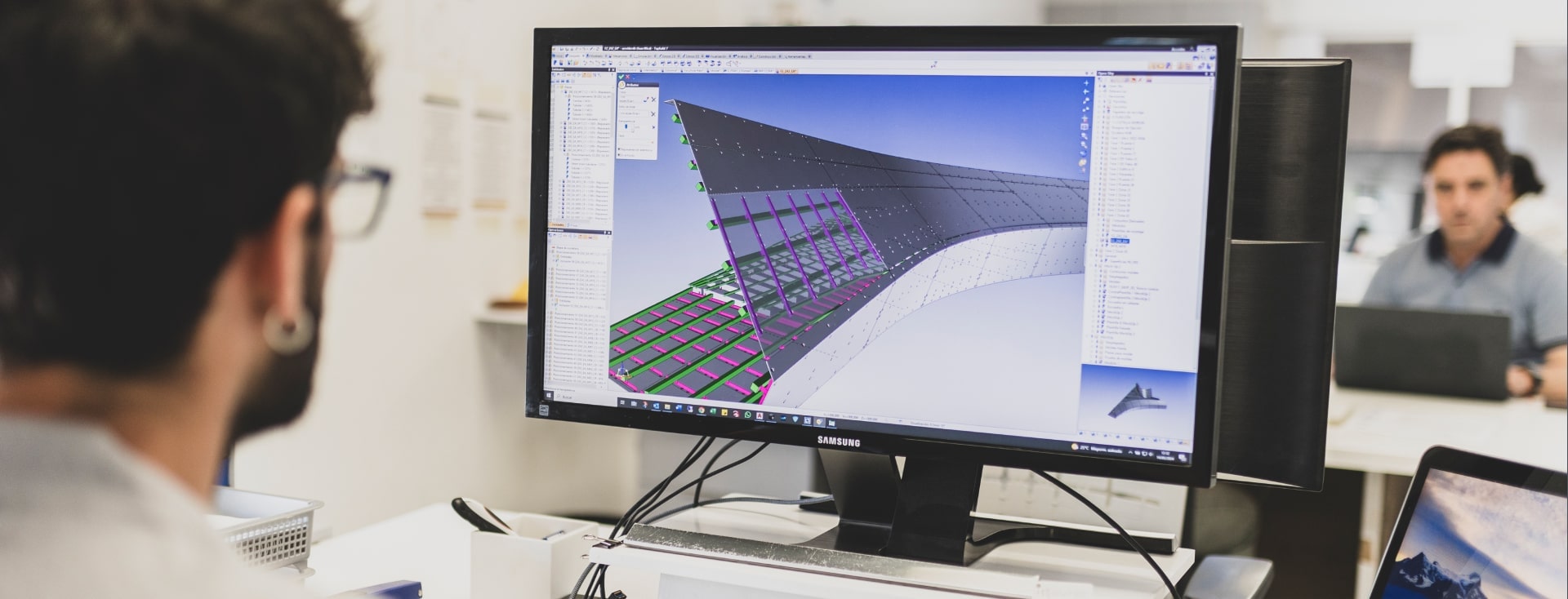

Solid Surface offers several advantages over traditional materials such as marble or granite, it can be moulded into complex shapes to suit different designs. In addition, its non-porous surface makes it more hygienic and easier to maintain compared to porous materials such as marble.

Solid Surface is installed using gluing and sealing techniques to achieve imperceptible joints. Once installed, maintenance is relatively simple. Regular cleaning with mild soap and water is recommended to keep the surface clean and prevent residue build-up.