Technical office

Our Technical Office, the best added value for our customers

We provide technical support to our client in all phases of the project to ensure the success of the project both in terms of quality requirements and cost objectives.

Technical capacity

From idea to reality

We combine machine technology for processing technical materials with the most advanced 3D design and CAD/CAM machining software on the market

Specialised machinery

5-axis CNC machining centres, thermoforming equipment, sanding machines and vacuum handling equipment for processing up to 2,000 m2 per week.

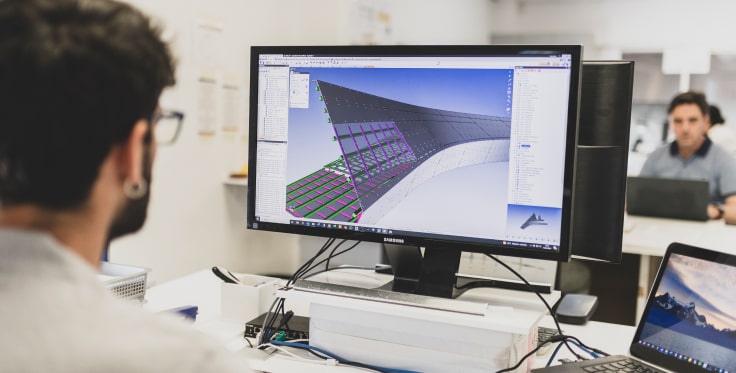

Top Solid CAD/CAM/PDM software

We work with TopSolid software, a tool that brings together innovation and technology to tackle all phases of the project.

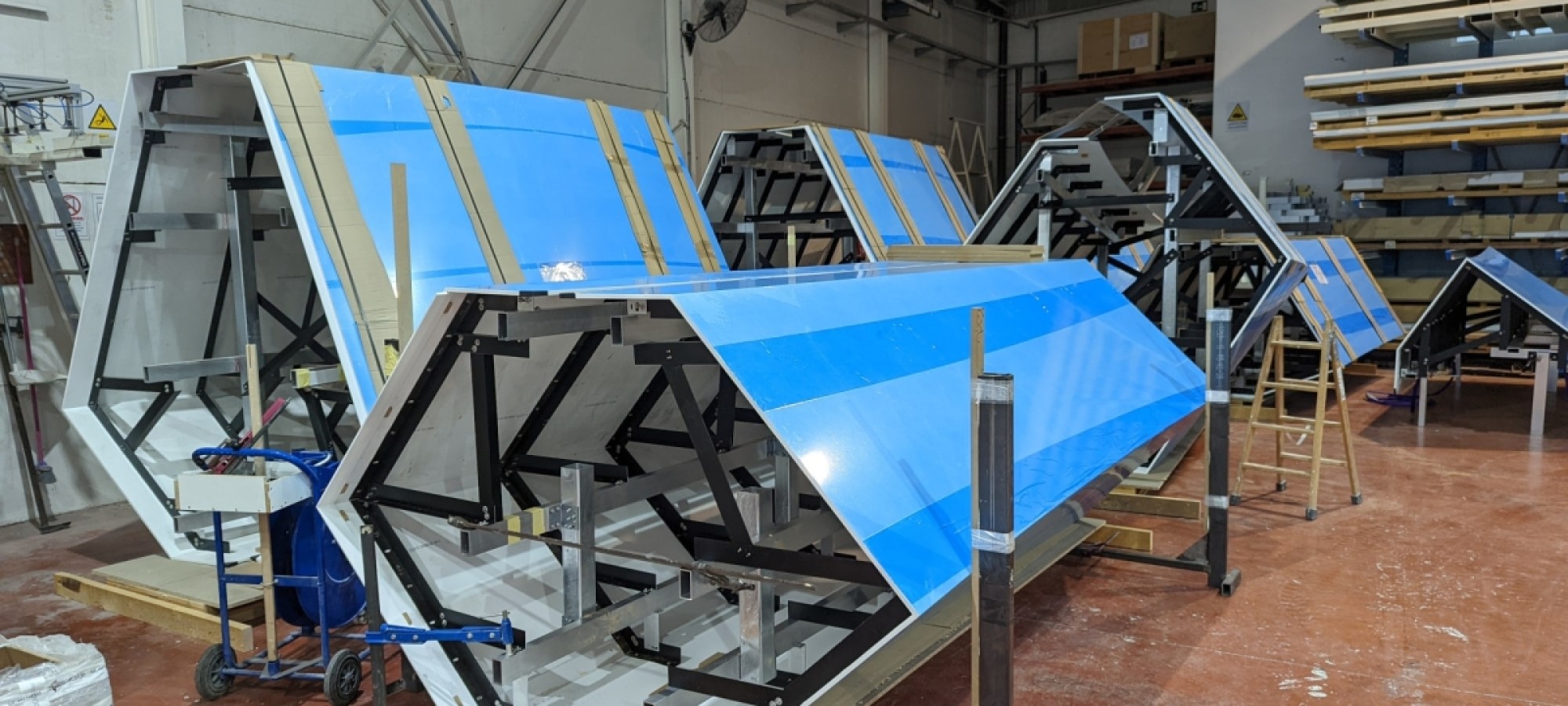

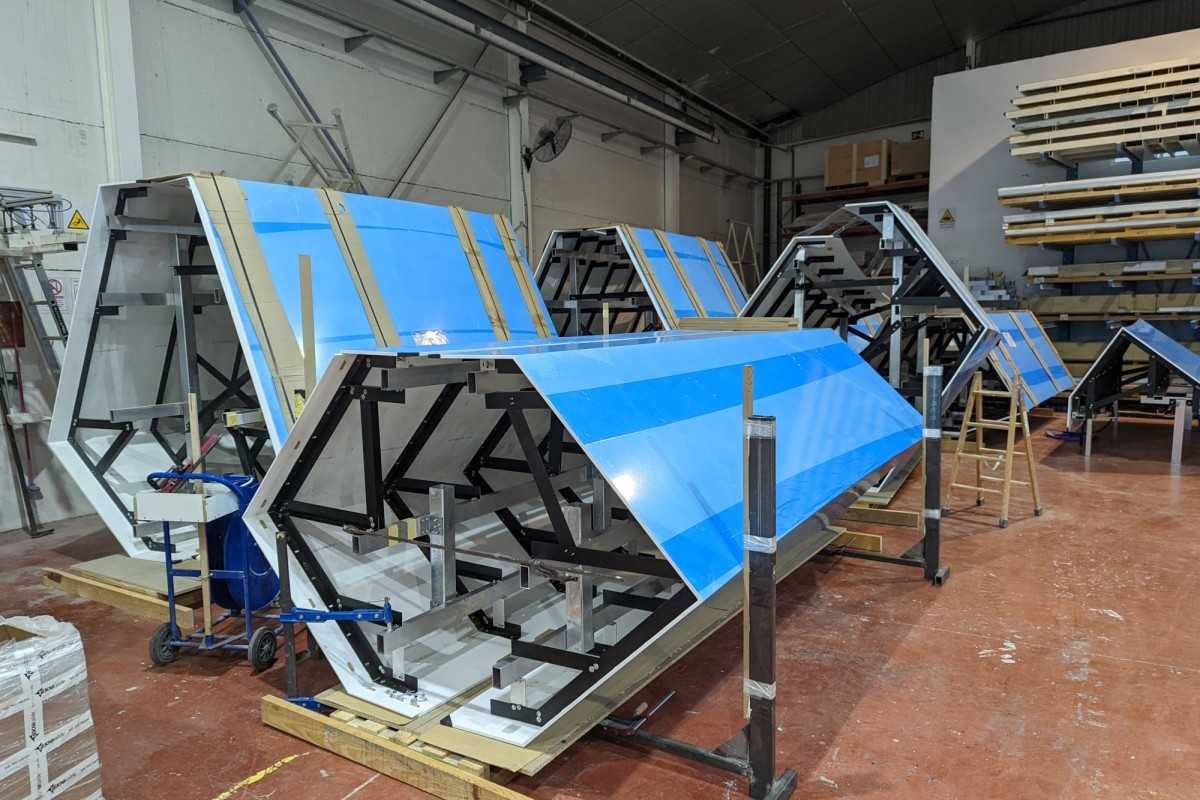

Prototype manufacturing

We work with customised prototypes, according to the requirements and complexity of each project to give our clients security and anticipation of production

Thinking ahead

We pursue a sustainable way of working. We seek to minimise our ecological impact by working in various areas, from the selection of raw materials to waste management

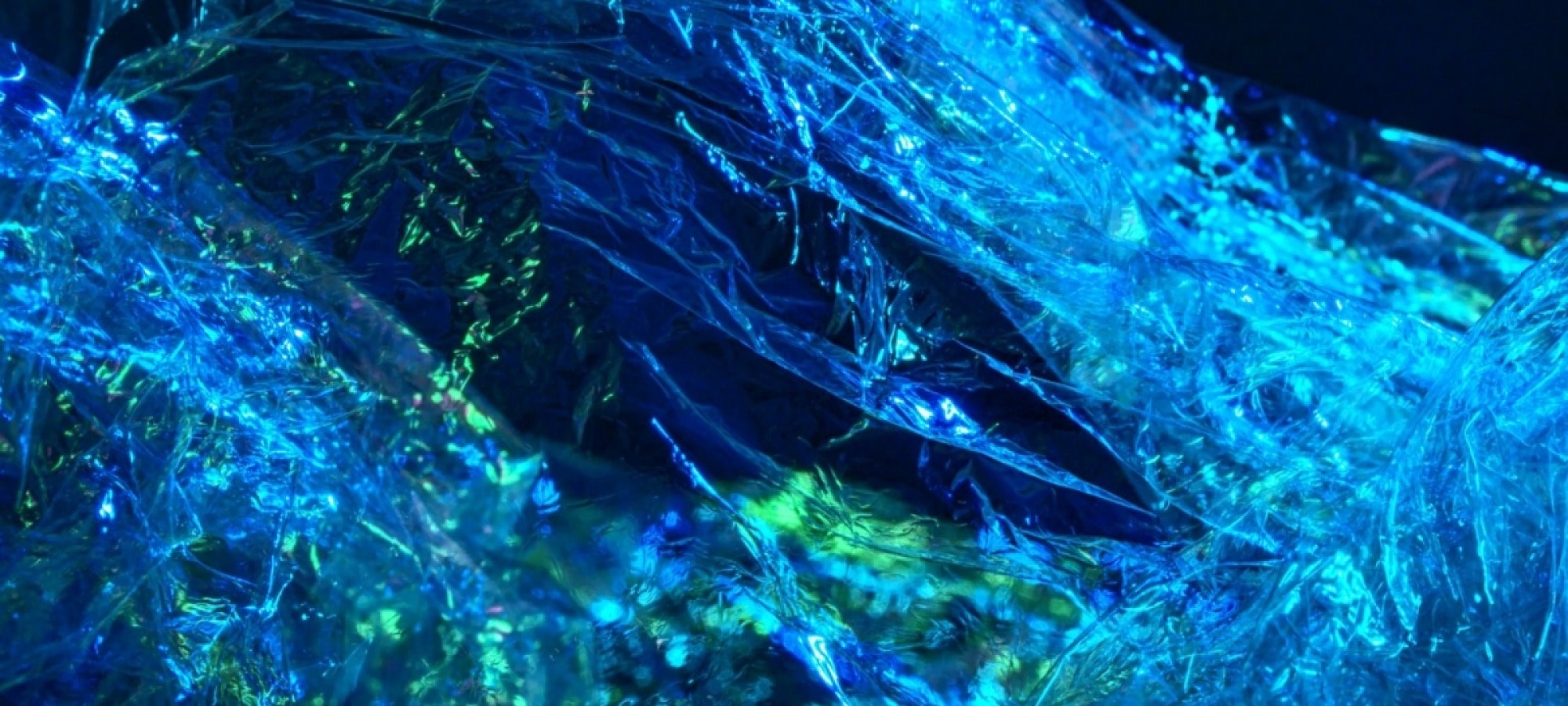

Recycled materials

We adapt to the project by proposing alternatives and whenever possible, prioritising the use of recycled materials in both raw materials and packaging material.

Waste sorting

We strive to minimise waste generation at all stages of our value chain and sort the waste generated to facilitate recycling.

Solar energy

We are committed to renewable energies. We are in the project phase for the installation of solar panels, our goal: to derive the consumption of production to clean energies.