Solid Surface in Valencia

Indutec Solid redefines Solid Surface joinery, combining advanced technology and innovative design to create exceptional solutions

Indutec Solid redefines Solid Surface joinery, combining advanced technology and innovative design to create exceptional solutions

At Indutec Solid, located in Valencia, we specialise in Solid Surface carpentry, tackling projects of any scale and complexity, especially in ventilated facades. Our collaboration with leading Solid Surface manufacturers guarantees high quality materials and innovative solutions for each project. Our technical office offers comprehensive design and development support, ensuring that each solution not only meets but also exceeds our customers' expectations.

We offer a wide range of products and applications including ventilated facades, home and bathroom furnishings, and interior kitchen and bathroom cladding. Our services extend to the manufacture of worktops, shower trays, retail furniture, and work areas for the sanitary sector. In addition, we design reception desks, work tables, and other industrial design products such as acoustic enclosures and loudspeakers. With the ability to transport and install our products anywhere in the world, Indutec Solid is your ideal partner for projects that require Solid Surface workshop and Krion workshop

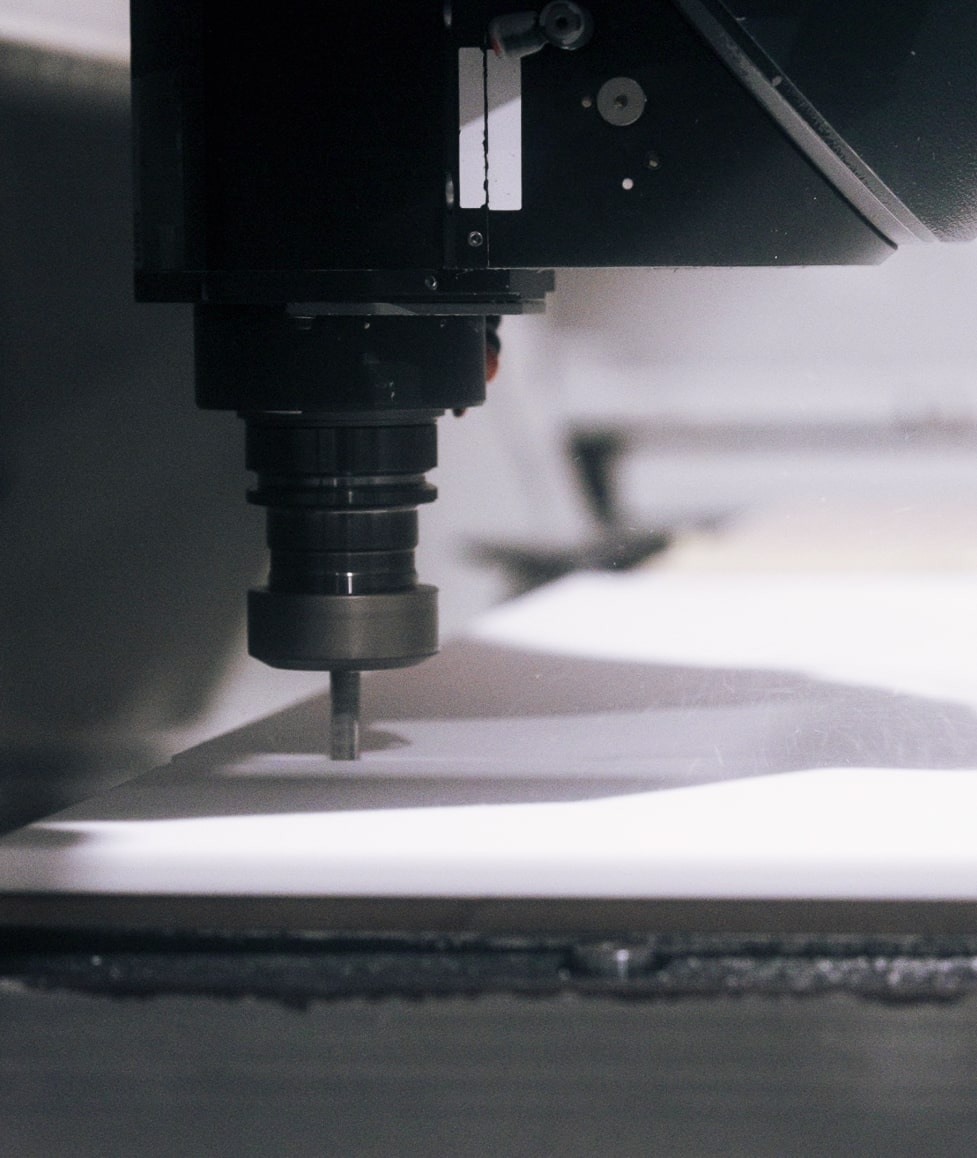

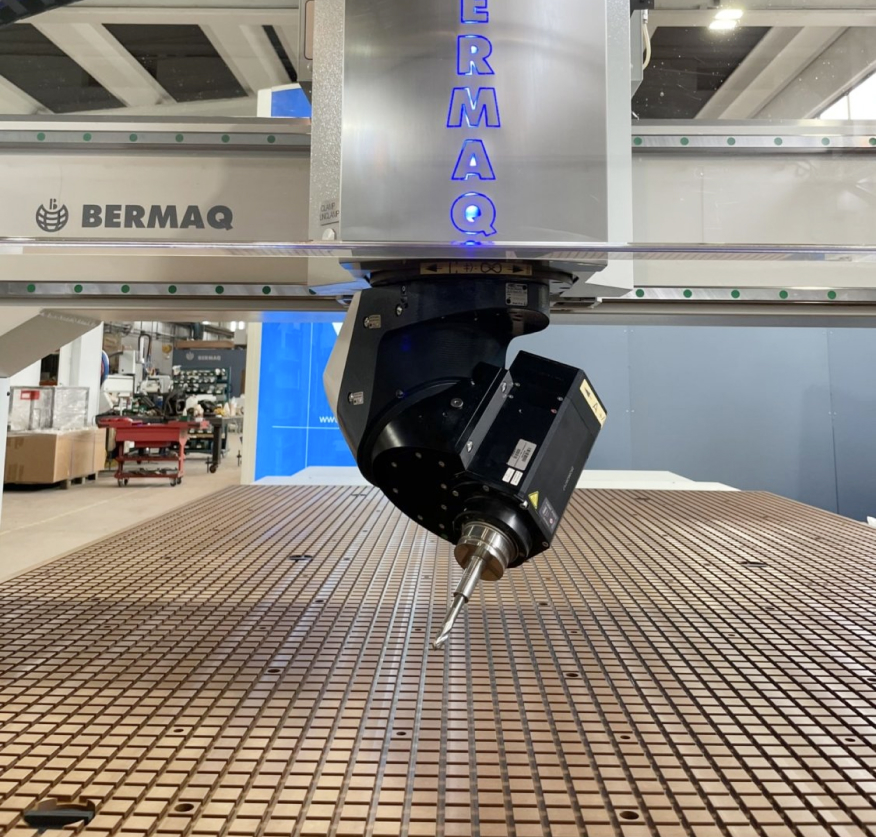

Indutec Solid is distinguished by its advanced technological infrastructure in the field of Solid Surface joinery. Our facilities include three 5-axis machining centres, with a working capacity of 4900x2500x1000 mm, which allows us to carry out precise cutting and shaping for large-scale projects. In addition, we have equipment such as plane sanders, squaring machines, hydraulic presses, and a thermocurving furnace, all essential to work Solid Surface materials to perfection.

These tools, along with our bridge cranes, enable us to handle large volumes of material and complex projects with efficiency and precision. The combination of our state-of-the-art technology and our team's extensive technical knowledge allows us to tackle and overcome the most demanding challenges, consolidating our position as market leaders in Krion workshop and other advanced materials. At Indutec Solid, every project is an opportunity to demonstrate our commitment to quality and innovation.

Over 2,000 m2 of facilities equipped with the latest technology to conceive complex and ambitious projects

In our 3 machining centers, we work with workpiece volumes of up to 5000x2300x1000 mm, leveraging TopSolid software to exploit all possibilities for producing parts with reliability and precision.

We leverage the use of different thermoforming technologies, adapting to the characteristics of the material and the complexity of the geometries required by each project.

Where we are?